Are you facing issues with stringing on your prints or struggling with flexible filaments? It might not be something you’re doing wrong—it might be your extruder! In the realm of 3D printers, there are primarily two systems for pushing filament through the hot end, where it undergoes melting: Bowden drive and direct drive. Many printers use the Bowden drive because it’s cheaper, but here’s the catch—direct drive extruders are a much better choice.

Best Direct Drive 3D Printer

In this guide, we will share the top direct drive 3D printers. We’ll break down what makes them special in the world of 3D printing. Whether you’re a pro or just starting with 3D creation, come along as we explore the important factors that make direct drive printers stand out.

We’re going to check out the important ones, the cool features, and what you need to consider that make direct drive 3D printers great for precise and flexible printing. But before we get into the nitty-gritty of each printer, let’s understand what a direct drive printer is.

What is Direct Drive 3D Printer?

A direct drive 3D printer is a special kind of 3D printing machine. Instead of a long tube guiding the printing material from a fixed part to the printing nozzle, the material goes directly from a moving part, where the motor is, to the nozzle. This shorter and more direct path helps control the material flow better, making the printing process more precise.

Let’s compare this with another setup called the Bowden extruder. In the Bowden system, the motor is fixed, and a long tube guides the material to the printing nozzle. While this setup reduces weight on the moving part of the printer, it brings challenges like potential issues with material movement and limitations in handling certain types of materials.

Resin 3D Printer vs Filament FDM Printer

Components of Direct Drive Printer

Now, looking at the key parts of a direct drive system:

- Extruder Motor: This is the motor that pushes and pulls the printing material directly to the printing nozzle.

- Hotend: The hotend is where the material gets melted, and it’s deposited layer by layer to create the 3D print.

- Mounting System: The direct drive extruder is usually attached to the moving part of the printer, so it moves along with it during the printing process.

- Short Filament Path: Unlike Bowden setups, direct drive systems have a short path for the material to travel before reaching the printing nozzle. This makes the printing more efficient and controlled.

Top Direct Drive 3D Printer extruder:

Here, we’ll discuss leading Direct Drive 3D Printers, review their features, and help you choose the most suitable one for your business.

1. Anycubic Kobra Neo 3D Printer

Anycubic is back with a more budget-friendly version of their popular Kobra 3D printer, called the Anycubic Kobra Neo. It’s a stripped-down version of the Kobra, maintaining key features like direct drive, PEI-coated flex plate, and auto bed leveling.

SPECIFICATIONS

Footprint of 445 x 443 x 490 mm

Build volume of 220 x 220 x 250 mm

Supports materials like PLA

PETG, TPU, and ABS.

Connectivity options include MicroSD and USB

2.4-inch color LCD with a knob interface. |

The main difference is the replacement of the touch screen with a smaller 2.4-inch color screen controlled by a knob. This adjustment saved $70, although the exact areas where cuts were made aren’t specified. You can spot certain design alterations, and there are common components shared with its counterpart, the Kobra Go.

Design:

The Kobra Neo boasts a design characterized by an aluminum alloy gantry with a sleek black etching, complemented by durable plastic components.

Notably, it maintains the textured PEI-coated spring steel plate, allowing for easy print removal when cooled.

Despite the slight design changes, including a smaller LED screen with a knob, the Kobra Neo remained user-friendly, with a bright, full-color screen and simplified icons. It comes with Ultimaker Cura 4.12 and three material profiles for PLA, ABS, and TPU.

Performance:

Performance-wise, the Kobra Neo matches the original Kobra, impressively going from unboxing to the first print in just 20 minutes. It boasts an easy-to-use direct drive and straightforward auto bed leveling, reducing challenges for new users. The PEI-coated steel flex plate ensures prints adhere when hot and release when cold, earning the Kobra Neo, the title of Best 3D Printer for Beginners.

While the Kobra Neo is suitable for any workshop, the absence of a third-party ecosystem and reliance on in-house parts might pose challenges for those wanting to modify or upgrade—a common preference among advanced users.

It features a direct drive extruder with a 0.4mm nozzle, a double-sided PEI spring steel heated build platform, and inductive auto leveling.

The Kobra Neo comes mostly assembled, with 90% of the setup done. It includes the necessary tools, side cutters, nozzle cleaner, grease, and a microSD card with a USB adapter. Additionally, a spare nozzle and a sample of PLA are provided. The assembly process is straightforward, taking around 20 minutes, thanks to clearly marked and easily plugged wiring.

Printing tests, including the owl, fox in two colors, a Japanese-inspired locking toolbox, and a detailed dragon bust, resulted in quality prints with minimal issues.

Verdict:

The Anycubic Kobra Neo stands out as a straightforward, no-fuss 3D printer suitable for beginners, offering quality prints and essential features at an affordable price. However, challenges may arise for those looking to modify or upgrade, and the Z height adjustment process might not be beginner-friendly.

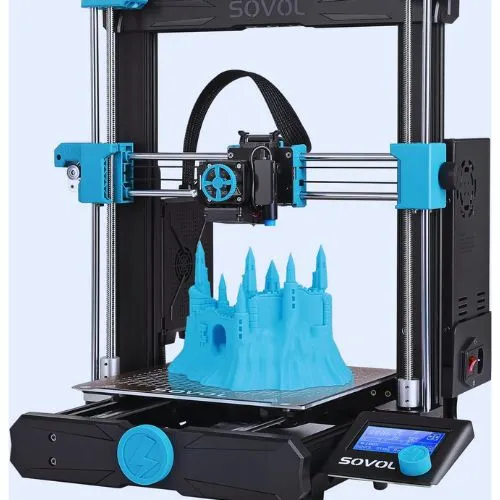

2. Sovol SV06 3D Printer

The Sovol SV06 is a decent, affordable 3D printer that’s great for beginners. It’s a mix of Prusa’s i3 printer and some Creality technology, as Sovol often sources parts from Creality.

.

The SV06 includes essential tools for setup:

- Side cutters

- Plastic scraper

- Spare nozzle

- MicroSD card with a USB adapter.

The machine has the classic i3 design in Sovol’s turquoise blue, with injection-molded plastic parts. It features a 220 x 220 bed and an old Ender 3 type screen, but it also has a powerful planetary drive extruder and an all-metal hotend.

The SV06 uses automatic bed leveling with an inductive sensor, and it employs sensorless homing and auto-aligning of the Z axis. Although it may not be the speediest option, it does support Klipper for users who want to delve into that possibility.

Setting up the SV06 requires more assembly compared to recent printers. This 3D printer comes with a complete leveling guide for accurate bed leveling.

For software compatibility, the SV06 can be used with PrusaSlicer with a slight modification to an MK3 profile. It comes with a sample coil of white PLA for your initial prints.

Testing and Opinion

Print tests, including Benchy and vase mode tulips, produced smooth results. The SV06 handles materials like PETG and TPU well. It’s reliable and affordable, making it suitable for makers who want quality prints without breaking the bank.

While it may not be as impressive as the Prusa MK4, it offers good value for money. If you’re looking for alternatives, the Anycubic Kobra Go, and Elegoo Neptune 3 Pro are worth considering for their quality prints and user-friendly features.

3. Original Prusa i3 MK3S+ 3D Printer:

Meet the Original Prusa i3 MK3S+ 3D Printer, the reigning champion of desktop direct drive 3D printers. This printer is like the Hulk of the 3D printing world—tough and super reliable.

.

The latest upgrade brings a superPINDA probe to the party, making your prints even better by enhancing the calibration and adhesion of the first layer. This FDM kit king comes with a bunch of cool features:

- It can recover a print after a power outage.

- It has a sensor to alert you when the filament is running out.

- It even has a quiet mode for nighttime or disturbance-free printing.

Plus, it’s open source, giving you the freedom to tinker and improve.

What sets Prusa apart is the top-notch quality of its parts. Prusa made a special extruder that directly pushes the filament. It has a fancy hot end and parts from Bondtech. You can make your Prusa even cooler by adding the Multi Material Upgrade 2.0. Then, you can print with five different filaments and colors altogether!

In a nutshell, the Prusa i3 MK3S+ is a heavyweight in the world of direct-drive 3D printers, loved by hobbyists and professionals alike for its durability, reliability, and continuous improvements. It’s the printer that keeps on giving.

User Reviews:

User experiences with the Prusa i3 MK3S+ 3D Printer vary widely. One satisfied customer, initially hesitant about the cost, was pleasantly surprised by its out-of-the-box performance, lauding its reliability, consistent temperatures, and user-friendly nature.

On the flip side, a contrasting viewpoint comes from an individual who chose to assemble the printer from a kit. This user expressed frustration with the assembly process, citing poor-quality components and alignment difficulties. Issues with the extruder compounded their problems, leading to challenges in obtaining replacement parts. Unfortunately, the unavailability of specific hardware from Prusa meant resorting to significant expenditures to resolve the encountered issues.

Verdict:

In a different scenario, a new 3D printing enthusiast opted for the Prusa MK3S+ based on its reputation, acquiring it from Amazon for quicker delivery. Their experience was positive, highlighting the receipt of an authentic product, a comprehensive toolset, and spare parts. They were able to achieve successful prints within minutes of setup.

4. ELEGOO Neptune 3 Pro FDM 3D Printer:

The ELEGOO Neptune 3 Pro is a 3D printer with some cool features. It can print stuff up to 8.85×8.85×11 inches, which is big enough for most things people want to print. The printer has some quiet stepper motors, so it doesn’t make a ton of noise while printing.

.

The printer features an intelligent system to ensure the bed is leveled precisely. It does this by scanning the bed and adjusting the height of the print head so everything comes out nice and even. If the printer runs out of filament or there’s a power outage, it stops and lets you pick up where you left off. Handy!

The ELEGOO Neptune 3 Pro 3D Printer has a special extruder made of strong stainless steel. It helps smoothly print various materials like PLA and TPU, reducing common printing issues. The nozzle kit has quality parts for better cooling and prevents clogging. The printer also has automatic bed leveling for precise prints and a smart feature that pauses and resumes printing in case of issues.

It’s a bummer when things don’t work as expected, and the company is still figuring out what’s wrong.

5. AnkerMake M5 3D Printer:

Anker promised a lot with this printer. They said it would be super fast, easy to set up, and come with cool features like an “AI camera” to save your prints and remote control over the internet. After a year of use, though, things didn’t quite live up to the hype.

.

REASONS TO BUY

✓Great and quick to set up

✓Printing speed impresses

✓Handles different plastics well.

✓Auto-leveling fixed via update.

REASONS TO AVOID

✗Vibrations affect print quality, noisy even at rest

Performance

When it comes to printing, the AnkerMake M5 is speedy, but there’s a catch. The prints don’t always turn out as smooth as expected, and there’s a weird effect called “ringing” or “ghosting” on many parts, which might be due to vibrations at high speeds.

The printer’s camera, supposed to save your prints from failure, didn’t work as well as promised. It didn’t catch prints slipping or breaking. Some users even reported issues with filament not coming out properly and the printer happily printing nothing.

Setting it up wasn’t as quick as they claimed. Some important stuff, like properly tightening belts and adjusting things, wasn’t covered in the instructions. It took a while for Anker to fix some issues with the printer’s firmware, like problems with leveling the bed and forgetting settings.

Customer Review:

The noise became an issue, too. The printer is so loud, even when idle that it had to be moved to the garage.

There’s a concern about safety. Some users shared scary pictures of failed prints causing a plastic explosion that could potentially damage the printer. When people reported issues, they sometimes had to prove the problem before Anker agreed to send replacement parts.

Quality control is a problem. Some printers had parts that were too loose, others had wheels that didn’t roll properly, and there were issues with screws breaking easily.

Anker promised an all-metal hotend during the Kickstarter campaign, but it turns out there’s still some plastic tubing inside.

Anker didn’t fully acknowledge these problems, saying they were within normal tolerance levels. They focused more on software improvements, but some users had a tough time at the beginning, with prints having gaps and bulges.

While things have improved, the printer still has its quirks, and Anker keeps making changes. They plan to switch their slicer software and release firmware updates, but users are crossing their fingers that these changes will make things better, not worse.

So, the AnkerMake M5 is a mixed bag. Some love it, and some have had a lot of issues. It’s a gamble.

Related Article: Best DTG Printer Under $5000 For Small Businesses

FAQs:

With direct drive in 3D printing, the filament goes straight into the extruder on the print head. This helps control filament better, especially with flexible materials. It avoids problems like filament retraction, making prints more accurate and consistent. Direct drive is great for different filaments, making it useful for various printing jobs.

How strong a 3D print is depends on what material you use and how you print it. Methods like Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM) with tough materials like Nylon or Polycarbonate usually make sturdy prints. Another way, Stereolithography (SLA) and Selective Laser Sintering (SLS), using special resins or powders, can also make strong and detailed prints. If you really need something super strong, people often like to use SLS printers because they can use many different strong materials.

Conclusion:

When seeking a reliable direct drive 3D printer, consider the AnkerMake M5 and ELEGOO Neptune 3 Pro. Both printers exhibit commendable features, with Neptune offering a smooth setup, dual-gear extruder, and auto bed leveling.

Meanwhile, the AnkerMake M5 impresses with fast printing and ease of assembly. However, bear in mind Anker’s quality control issues and Neptune’s reported noise concerns. Ultimately, choose based on your priorities, whether it’s speed, ease of use, or specific features.